Advanced Printed Electronic Solutions (APES) is a systems integrator, 3D printing service, and consultancy partner for additively manufactured electronics. 3D printed electronics machines have been around, but a truly scalable, manufacturing-ready solution has so far been absent from the industry. Today, in conjunction with RAPID+TCT, APES has unveiled a solution that could significantly expand the volume of 3D printing for circuits, traces, packaging, and sensors.

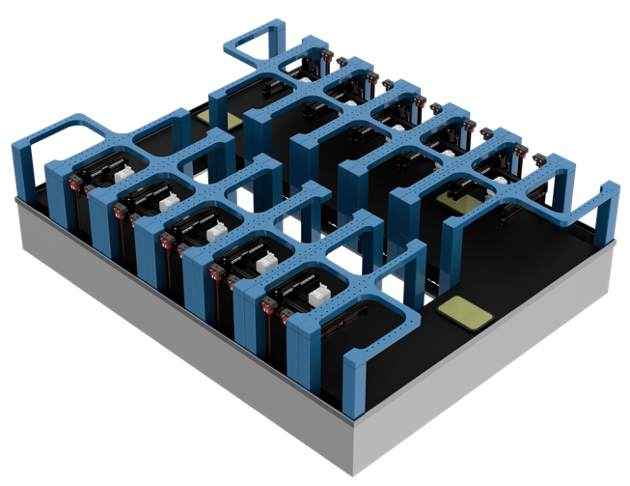

The Matrix6D is a modular 3D printing solution featuring movable maglev conveyor platforms that travel beneath various print heads. These build platforms are propelled from one tool head to another via magnetic levitation. At each station, different steps can be performed. For example, a polymer housing might be deposited by one tool head, after which the build is transferred to a circuit 3D printing head, then milled by another head, and finally returned to the polymer deposition station to complete the housing. This is just one possible workflow—numerous tool heads could introduce a wide range of materials and even distinct 3D printing processes into the mix.

While the floating maglev platforms may sound like science fiction, similar technologies have long been used in semiconductor and other high-end manufacturing applications. I find this to be a highly compelling vision for 3D printed electronics. In fact, among all the futuristic factory-type concepts I’ve encountered, this is likely one of my favorites.

A line-based approach, a factory-in-a-tool model, or even racetrack-type systems could also work. However, I find the multidirectional, multi-head, and multi-platform concept especially versatile. Track, line, and factory-in-a-tool setups can also accommodate complex builds using multiple heads, but any delay affects the entire system. In contrast, adding a spare tool in a system like Matrix6D could provide additional capacity if a tool is delayed, broken, or stalled. A single spare for a finicky head can enhance overall system resilience, and spares for all tools could absorb potential errors across the setup.

While this may initially seem inefficient, the actual effectiveness depends on system-wide cost and utility. Extra resilience might prove valuable if it ensures timely delivery and more efficient capital expenditure use. In many ways, this production model resembles an inkjet head—precision-engineered and resilient by design.

Matrix6D could be rapidly reconfigured and highly responsive to demand fluctuations. With sufficient data, you could optimize for resilience and potentially alter the order of operations. For instance, if an error is detected, a build plate could be rerouted to a tool that removes the previous layer, minimizing downtime. I genuinely believe this approach could make Matrix6D the definitive vision for the future of digital manufacturing.

“Every customer we’ve worked with asks the same question: how do we scale 3D printing beyond prototyping? 6D is our answer, It’s a clean-sheet reimagining of the additive factory—adaptive, software-defined, and built for mass customization and true production volume,” said APES CEO Rich Neill.

The matrix layout of the factory is composed of configurable grids, offering flexibility in design and operation. Various gantry options are available, and the current toolheads include inkjet, direct ink write, dispensing, pick-and-place, aerosol jet, curing, post-processing, milling, and extrusion. This broad range of technologies enables the production of a diverse array of components. The system also integrates with QA processes and supports scanning.

Each tool is designed to calibrate itself, and the technology is adaptable to different scales and accuracy levels, accommodating multiple modalities. Parts can be customized, serialized, or parallelized, depending on the application. APES anticipates that IC packaging, circuit boards, and optics will be the initial areas of deployment.

A demo version of the tool is available at RAPID, booth 1325, where the critical software that routes platforms and manages operations will also be showcased. I find this to be a highly compelling vision for the future of additive production and will be following its development closely.

Leave a Comment